中国粉体网讯 陶瓷材料在烧结过程中存在自发收缩,特别是高气孔率泡沫陶瓷,其烧结收缩率高达40~80vol%。近日,清华大学材料学院杨金龙教授课题组和瑞士联邦理工大学André Studart教授课题组发明了一种通过金属颗粒自组装制备超稳定的泡沫浆料,首次基于金属颗粒的柯肯达尔效应制备了烧结无收缩且性能优异的Al2O3陶瓷及Al2O3/Al复合材料,揭示了Al核/Al2O3壳层结构在热氧化过程中发生的空心化过程及机理,并进一步利用亚微米级粉体原位空心化造成的膨胀与粉体烧结收缩相抵消,真正实现了陶瓷材料的烧结零收缩甚至是负收缩制备,是一种颠覆性的技术创新。

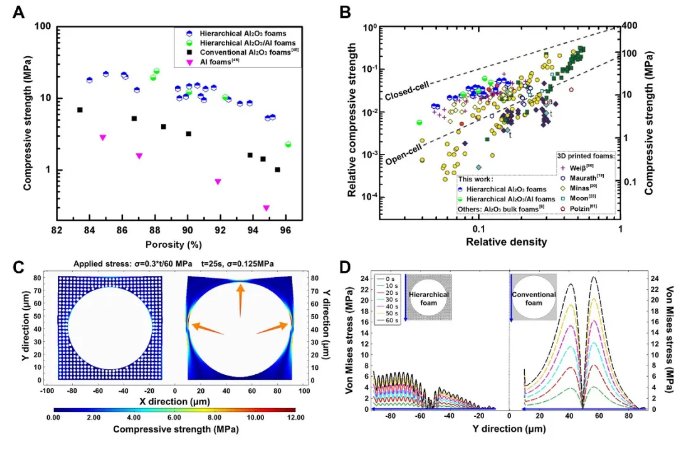

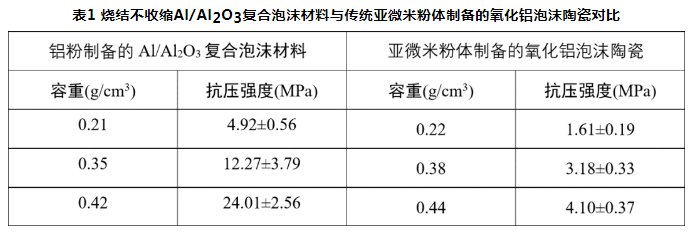

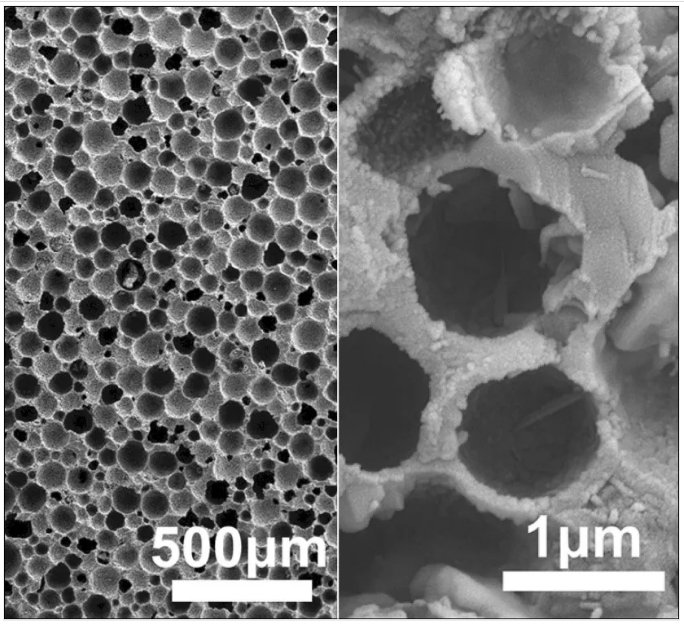

通过在亚微米级尺度构建多级孔结构,这种新型的空心球组装材料具有超高的力学性能,气孔率为90%的氧化铝泡沫陶瓷抗压强度高达14.8MPa,可见报道类似泡沫陶瓷的2~10倍,如图1和表1所示。图2为多级孔氧化铝泡沫陶瓷显微结构。该研究工作还论证了该思路结合3D打印、冷冻注模工艺、凝胶注模成型工艺等不同方式构建多级孔材料的普适性,为近净尺寸制备轻质高强陶瓷材料提供了新思路。

相关研究成果申请发明专利,并以“Ultra-strong hierarchical porous materials via colloidal assembly and oxidation of metal particles”为题发表在期刊Advanced Functional Materials (Impact Factor: 16.836)。主编和审稿人对该研究工作给予高度评价:“Should be published as a VIP paper. The paper constitutes a significant advance in both science and technology of materials. The novel process enables producing porous alumina ceramics with higher strengths than by other processes particularly in the very highly porous region (between 85 and 95%). The ability to produce such materials with near zero change in dimensions during sintering has significant advantages in economically manufacturing complex shaped components from these materials. There are several clever scientific advances as well. The use of the Kirkendall effect to create the "hollow" particles within a macroscopic green body is quite clever. The ability to control the shrinkage/expansion to near zero by considering the volume expansion during oxidation and sintering shrinkage is a significant contribution to the state of the art in ceramic processing. The demonstration that the approach can be used in combination with 3D printing, freeze casting and gelcasting provides confidence that the approach can be used to manufacture complex shaped components.”

图1 空心微珠组装多级孔陶瓷的力学性能

表1 烧结不收缩Al/Al2O3复合泡沫材料与传统亚微米粉体制备的氧化铝泡沫陶瓷对比

图2 多级孔氧化铝泡沫陶瓷显微结构

该论文通讯作者为清华大学材料学院杨金龙教授和瑞士联邦理工大学材料系André Studart教授,第一单位为清华大学材料学院,霍文龙博士与张笑妍博士为该文的共同第一作者。

(中国粉体网编辑整理/平安)

注:图片非商业用途,存在侵权告知删除!